Safety – arguably one of the world’s most boring topics. Ask anyone who’s not a new parent or human resources professional about safety, and their eyes will likely glaze over. We all know that safety is important , but let’s be real: how many times do you actually listen to the safety announcements on your flight or read all of the safety procedures in the employee handbook? When things are going along in your business day to day, safety is rarely a thought on the mind of business owners, field technicians, and dispatchers.

Safety doesn’t matter , until it does. You don’t care about safety or appreciate it until something goes wrong. You don’t think about the oxygen masks on the airplane until your flight hits turbulence. You don’t appreciate the airbags and crumple zones in your car until your car gets into a crash.

For as much as we overlook it and take it for granted, safety products and procedures have very real, substantial impacts on our lives and businesses. Airbags reduce passenger fatality in crashes by up to 30%. The lost productivity in the United States due to workplace injuries, often from unsafe practices, costs employers $62 billion per year , more than the GDP of 91 countries.

And that’s just physical safety , what about the safety of your business? We’ve all rolled our eyes at HR-mandated seminars on workplace practices and compliance. But these activities have very real costs as well. The average case of timesheet fraud costs a company over $70,000. When an employee does substandard work for a customer, that can end with your company in court , thousands of dollars in court fees and settlements, not to mention the cost of a damaged reputation. In some cases when substandard work is provided, a contractor or business owner can end up in jail.

These scenarios are enough to keep business owners up at night , but they can be mitigated and risk can be easily managed with the right practices. For contractors and service businesses, field service management software can help to minimize risk to employees, owners, and customers , keeping everyone happy and out of trouble.

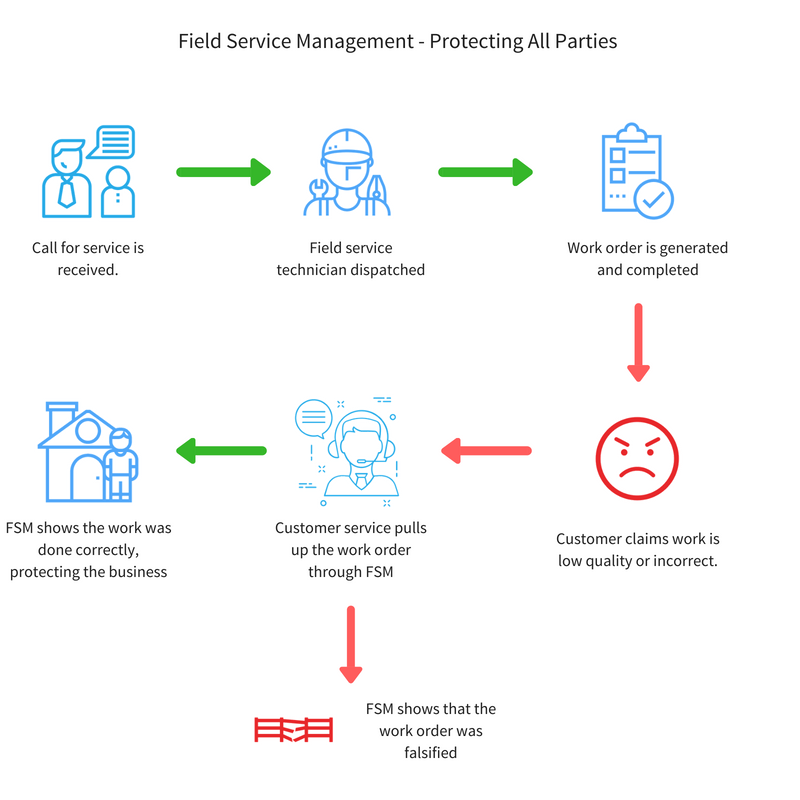

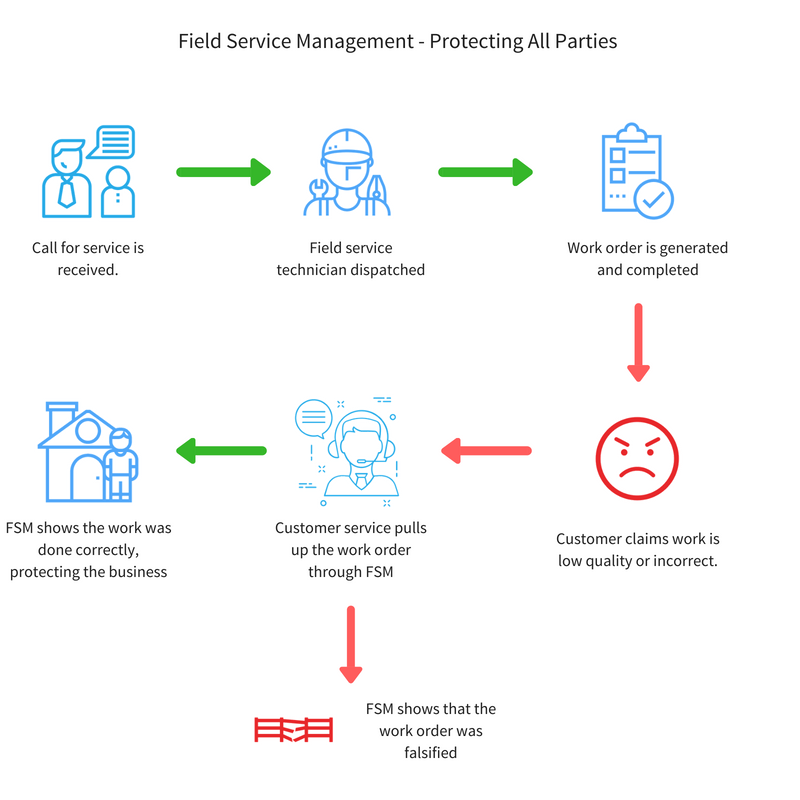

Proof of Work and Labor

The core of FSM programs is work order management for both the office and the customer , the office is able to outline what the customer requests are, giving the technician the right information to complete the job. The customer then receives a digital invoice and documents for the work order, showing them the work was completed for their records. This digital trail is the most basic utility provided by FSM, available in every system from the most basic to enterprise-level deployments, but it’s also one of the most powerful utilities that keeps businesses and their employees safe from legal liability in a number of ways.- By using a FSM application, technicians can attach photos, videos, inspection forms and more to the work order , visual proof of the work completed.

- Many FSM applications have geo-tracking for mobile devices. This allows system administrators to see where there technicians are throughout the course of the day.

- Some field service applications provide an audit log for work orders and customer records , which allow business owners to see a full history of how a work order has been edited.

- Some field service applications allow for technicians to complete digital forms, such as an inspection report or installation checklist. These steps ensure that procedures and protocol are followed.

- Tom completed the work order for Cindy with photos and videos attached, with timestamps, of the cabinets being installed and completed. Tom has completed the installation checklist, and his geo-tracking shows that he was at Cindy’s house at the appropriate date and time. Cindy is clearly making up a story to get free cabinets, and Bob has the proof to take to court so that he can protect his business.

- Tom completed the work order, but did not attach photos or videos with timestamps, or complete an installation checklist. The audit log shows that Tom logged in and changed the work order after the fact. Geo-tracking shows Bob that when Tom was supposed to be at Cindy’s house, he was actually at the baseball stadium. Bob now understands that Cindy has a legitimate complaint, and can work with her to make things right. (Tom is probably also going to get fired).

Preventing Safety Hazards

The world of field service can be fraught with danger at times , climbing ladders, power tools, electrical equipment, and heavy machinery all have the potential to cause injury. Some industries are more dangerous then others , roofing, for example, has the fifth-highest death rate among all construction industries with 30 deaths per 100,000 FTE works. There’s no shortage of injuries in the field service and construction space contributing to that $62 billion in lost productivity per year. In addition to hazards for workers, there are risks for customers as well. A improperly installed electrical system can cause fire, electrocution, and even death. Collapsing roofs, falling fans, improperly constructed walls , all have the potential to cause serious injury. In some field service industries, the risks can be even bigger, such as the field service companies responsible for medical device repair. No software is a replacement for proper safety practices , and unfortunately, the manual nature of field service means that accidents and injuries will occasionally happen. But, the right FSM with the right procedures can minimize the risk of harm for contractors and patients.- Work orders or digital forms with required or sequenced steps ensure that field technicians are following the right safety procedures in the field. For example: they can not move to the next step of the work order without confirming that the main power to the home has been shut down.

- Timesheets and geo-tracking require technicians to log time and travel , ensuring that regulations regarding the amount of time worked are within legal guidelines.

- Attached documents to work orders such as disclaimers can be used to inform customers of potential hazards with new equipment or construction in their home.

- Asset management and recurring schedules allow service teams to create service schedules for equipment such as furnaces and ventilation systems , allowing them to make sure that these items are operating correctly and not causing harm to customers.

Legal Risks and Compliance

The lifecycle of field service management and safety doesn’t end with customers, technicians and business owners. In many industries, regulatory bodies such as the EPA, FDA, and local governing agencies have requirements for work performed in the field. And the risks can be drastically higher. Sure, Cindy the customer from our earlier example can sue you for a few grand and smudge up your reputation , but if you violate the rules set forth by the federal or state government, you could end up with not only a steep fine, but in some cases you can lose your business or even be sentenced to jail time. Legal compliance generally is only a concern for specialized field service industries , maid services or a garage door repair service don’t have much to worry about. But for the industries that do have a high risk of legal issues, the penalties for non-compliance can be extremely high. Examples of industries where regulatory bodies have substantial influence include the following:- Commercial Pest Control: Particularly for companies who deal with food processing plants, restaurants, and public buildings; commercial pest control companies need to document their usage of pesticides and chemicals per environmental agency guidelines.

- Exhaust System Cleaning: For companies that clean exhaust systems for restaurants, they need to be able to provide documents of what they did and when for their customers. Restaurants that do not have proof of exhaust cleaning can be closed by the board of health, and put the exhaust system cleaning company on the hook for liability.

- Medical Device Repair: The FDA has strict guidelines for companies that deal with the repair and installation of equipment in hospitals. For companies providing these services and the hospitals with this equipment, they need to have full records of the equipment maintenance history. Per the UDI Compliance mandate, every piece of equipment that touches a patient must have a barcode that identifies it, and every work order must be linked to a serial number.